From inside (document excerpt):

Part No. 08164SL Service Manual WorkmanR MDE Preface The purpose of this publication is to provide the service technician with information for troubleshooting, testing and repair of major systems and components on the Workman MDE. REFER TO THE OPERATOR’S MANUAL FOR OPERATING, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS. For reference, insert a copy of the Operator’s Manual and Parts Catalog for your machine into Chapter 2 of this service manual.

Lawn Mowing User Manual Free Download. Power Lawn Mower Free Instruction Manual Download PDF.

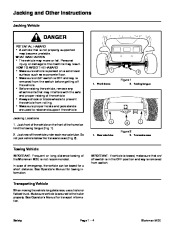

Additional copies of the Operator’s Manual and Parts Catalog are available on the internet at www.Toro.com. The Toro Company reserves the right to change product specifications or this publication without notice. This safety symbol means DANGER, WARNING or CAUTION, PERSONAL SAFETY INSTRUCTION. When you see this symbol, carefully read the instructions that follow. Failure to obey the instructions may result in personal injury. NOTE: A NOTE will give general information about the correct operation, maintenance, service, testing or repair of the machine. IMPORTANT: The IMPORTANT notice will give important instructions which must be followed to prevent damage to systems or components on the machine. E The Toro Company – 2008 This page is intentionally blank. Workman MDE Table Of Contents Safety Electrical Diagrams Chassis Transaxle and Brakes Electrical System Product Records and Maintenance Chapter 1 – Safety Safety Instructions 1 — 2 Jacking and Other Instructions . 1 — 4 Safety and Instruction Decals 1 — 5 Chapter 2 – Product Records and Maintenance Product Records . Maintenance . Equivalents and Conversions Torque Specifications . Chapter 3 – Electrical System General Information 3 — 2 Electrical Diagrams . 3 — 3 Vehicle Operation 3 — 4 Special Tools 3 — 5 Troubleshooting 3 — 8 Adjustments 3 — 11 Component Testing 3 — 14 Service and Repairs . 3 — 28 LESTER ELECTRICAL TECHNICIAN SERVICE GUIDE Chapter 4 – Transaxle and Brakes General Information 4 -Specifications 4 -Troubleshooting 4 -Service and Repairs 4 -SPICER OFF–HIGHWAY COMPONENTS MODEL 12 (ELECTRIC) MAINTENANCE MANUAL Chapter 5 – Chassis General Information Specifications Troubleshooting Service and Repairs Chapter 6 – Electrical Diagrams Electrical Schematic 6 — 3 Electrical Circuit Drawings . 6 — 4 Electrical Harness Drawings . 6 — 7 5 5 5 5 -1 2 3 5 2 3 4 6 2 -2 -2 -2 -1 1 2 3 Workman MDE This page is intentionally blank. Workman MDE Chapter 1 Safety Safety Table of Contents SAFETY INSTRUCTIONS Before Operating While Operating . Maintenance and Service JACKING AND OTHER INSTRUCTIONS . Jacking Vehicle . Towing Vehicle Transporting Vehicle . SAFETY AND INSTRUCTION DECALS 2 2 2 3 4 4 4 4 5 Workman MDE Page 1 – 1 – Safety Safety Instructions The Workman MDE is designed and tested to offer safe service when operated and maintained properly. Although hazard control and accident prevention are partially dependent upon the design and configuration of the machine, these factors are also dependent upon the awareness, concern and proper training of the personnel involved in the operation, transport, maintenance and storage of the machine. Improper use or maintenance of the machine can result in injury or death. To reduce the potential for injury or death, comply with the following safety instructions. WARNING To reduce the potential for injury or death, comply with the following safety instructions. Before Operating 1. Review and understand the contents of the Operator’s Manual and Operator’s DVD before starting and operating the vehicle. Become familiar with the controls and know how to stop the vehicle and engine quickly. Additional copies of the Operator’s Manual are available on the internet at www.Toro.com. 2. Keep all shields, safety devices and decals in place. If a shield, safety device or decal is defective, illegible or damaged, repair or replace it before operating the machine. Also tighten any loose nuts, bolts or screws to ensure machine is in safe operating condition. While Operating WARNING The Workman MDE is an off-highway vehicle only. It is not designed, equipped or manufactured for use on public streets, roads or highways. 1. Sit on the operator seat when starting and operating the vehicle. 2. Before starting the vehicle: A. Make sure that the battery charger is disconnected from the vehicle charger receptacle. B. Engage the parking brake. C. Make sure accelerator pedal is not depressed. D. Check position of forward/reverse switch and Hi/ Low speed switch. 3. Before getting off the operator seat: A. Stop vehicle, turn on/off switch OFF and remove key from switch. B. Apply the parking brake. 4. If vehicle is parked on incline, chock or block the wheels after getting off the vehicle. Safety Page 1 – 2 – Workman MDE Maintenance and Service 1. Before servicing or making adjustments to the vehicle, stop vehicle, turn on/off switch to OFF, engage parking brake and remove key from the on/off switch. 2. Make sure machine is in safe operating condition by keeping all nuts, bolts and screws tight. 3. Do not use open pans of flammable cleaning fluids for cleaning parts. 4. Keep battery area free of excessive grease, grass, leaves and dirt. 5. Disconnect batteries before servicing the machine. Carefully remove one of the battery cables from the battery pack as the first step in any repair. Once a battery cable has been removed, the electrical system on the vehicle can be safely worked on. Take care during repairs, however, to not allow tools or vehicle components to complete the battery circuit that was opened with the cable removal. Reattach the removed cable to the battery pack as the last step in any repair. 6. When using metal, uninsulated tools around batteries, do not allow tools to contact both positive and negative battery terminals simultaneously. 7. Remove jewelry and watches before servicing electrical components of the vehicle. 8. Battery acid is poisonous and can cause burns. Avoid contact with skin, eyes and clothing. Protect your face, eyes and clothing when working with batteries. 9. Battery gases can explode. Keep cigarettes, sparks and flames away from the batteries. Always service, store and charge the vehicle batteries in a well ventilated area. 10.Never use an open flame to check level or leakage of battery electrolyte. 11. When connecting the battery charger to the vehicle, connect the charger cord to the vehicle charger receptacle before plugging the charger power cord into an outlet. After charging the vehicle batteries, unplug the charger power cord from the outlet before disconnecting the charger cord from the vehicle charger receptacle. 12.If major repairs are ever needed or assistance is desired, contact an Authorized Toro Distributor. 13.To assure optimum performance and continued safety of the machine, use genuine Toro replacement parts and accessories. Replacement parts and accessories made by other manufacturers may result in nonconformance with safety standards and the warranty may be voided. 14.When raising the machine to change tires or to perform other service, use correct blocks, hoists and jacks. Make sure machine is parked on a solid level surface such as a concrete floor. Prior to raising the machine, remove any attachments that may interfere with the safe and proper raising of the machine. Always chock or block wheels. Use jack stands to support the raised machine. If the machine is not properly supported by jack stands, the machine may move or fall, which may result in personal injury (see Jacking Instructions in the Operator’s Manual and in this Chapter). Workman MDE Page 1 – 3 – Safety Safety Jacking and Other Instructions Jacking Vehicle DANGER POTENTIAL HAZARD · A vehicle that is not properly supported may become unstable. WHAT CAN HAPPEN · The vehicle may move or fall. Personal injury or damage to the machine may result. HOW TO AVOID THE HAZARD · Make sure vehicle is parked on a solid level surface, such as a concrete floor. · Make sure on/off switch is OFF and key is removed from the switch before getting off the vehicle. · Before raising the vehicle, remove any attachments that may interfere with the safe and proper raising of the vehicle. · Always chock or block wheels to prevent the vehicle from rolling. · Make sure proper hoists and jack stands are used to raise and support the vehicle. Jacking Locations 1. Jack front of the vehicle on the front of the frame behind the towing tongue (Fig. 1). 2. Jack rear of the vehicle under each rear axle tube. Do not jack vehicle below the transaxle case (Fig. 2). 1 Figure 1 1. Front frame 2 2. Towing tongue 1 2 Figure 2 1 1. Rear axle tube 2. Transaxle case Towing Vehicle IMPORTANT: Frequent or long distance towing of the Workman MDE is not recommended. In case of emergency, the vehicle can be towed for a short distance. See Operator’s Manual for towing information. IMPORTANT: If vehicle is towed, make sure that on/ off switch is in the OFF position and key is removed from switch. Transporting Vehicle When moving the vehicle long distances, use a trailer or flatbed truck. Make sure vehicle is secured to the trailer properly. See Operator’s Manual for transport information. Safety Page 1 – 4 – Workman MDE Safety and Instruction Decals There are several safety and instruction decals attached to your Workman vehicle. If any decal becomes illegible or damaged, install a new decal. Part numbers are listed in the Parts Catalog. Order replacement decals from your Authorized Toro Distributor. Safety Safety Workman MDE Page 1 – 5 – This page is intentionally blank. Safety Page 1 – 6 – Workman MDE Chapter 2 Product Records and Maintenance Table of Contents PRODUCT RECORDS . MAINTENANCE . EQUIVALENTS AND CONVERSIONS . Decimal and Millimeter Equivalents U.S. to Metric Conversions . TORQUE SPECIFICATIONS Fastener Identification . Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series) . Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Fasteners) . Other Torque Specifications Conversion Factors 1 1 2 2 2 3 3 4 5 6 6 Product Records and Maintenance Product Records Insert Operator’s Manual and Parts Catalog for your Workman vehicle at the end of this chapter. Additionally, if any optional equipment or accessories have been installed to your Workman, insert the Installation Instructions, Operator’s Manuals and Parts Catalogs for those options at the end of this chapter. Maintenance Maintenance procedures and recommended service intervals for the Workman MDE are covered in the Operator’s Manual. Refer to that publication when performing regular vehicle maintenance. Workman MDE Page 2 – 1 – Product Records and Maintenance Equivalents and Conversions 0.09375 Product Records and Maintenance Page 2 – 2 – Workman MDE Torque Specifications Recommended fastener torque values are listed in the following tables. For critical applications, as determined by Toro, either the recommended torque or a torque that is unique to the application is clearly identified and specified in this Service Manual. These Torque Specifications for the installation and tightening of fasteners shall apply to all fasteners which do not have a specific requirement identified in this Service Manual. The following factors shall be considered when applying torque: cleanliness of the fastener, use of a thread sealant (e.g. Loctite), degree of lubrication on the fastener, presence of a prevailing torque feature (e.g. Nylock nut), hardness of the surface underneath the fastener’s head or similar condition which affects the installation. As noted in the following tables, torque values should be reduced by 25% for lubricated fasteners to achieve the similar stress as a dry fastener. Torque values may also have to be reduced when the fastener is threaded into aluminum or brass. The specific torque value should be determined based on the aluminum or brass material strength, fastener size, length of thread engagement, etc. The standard method of verifying torque shall be performed by marking a line on the fastener (head or nut) and mating part, then back off fastener 1/4 of a turn. Measure the torque required to tighten the fastener until the lines match up. Fastener Identification Grade 1 Grade 5 Grade 8 Class 8.8 Class 10.9 Inch Series Bolts and Screws Figure 1 Metric Bolts and Screws Figure 2 Workman MDE Page 2 – 3 – Product Records and Maintenance Product Records and Maintenance Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series) Grade 1, 5 & 8 with Thin Height Nuts SAE Grade 1 Bolts, Screws, Studs & Sems with Regular Height Nuts (SAE J995 Grade 2 or Stronger Nuts) SAE Grade 5 Bolts, Screws, Studs & Sems with Regular Height Nuts (SAE J995 Grade 2 or Stronger Nuts) SAE Grade 8 Bolts, Screws, Studs & Sems with Regular Height Nuts (SAE J995 Grade 5 or Stronger Nuts) Thread Size in-lb # 6 — 32 UNC # 6 — 40 UNF # 8 — 32 UNC # 8 — 36 UNF # 10 — 24 UNC # 10 — 32 UNF 1/4 — 20 UNC 1/4 — 28 UNF 5/16 — 18 UNC 5/16 — 24 UNF 48 + 7 53 + 7 115 + 15 138 + 17 ft-lb 3/8 — 16 UNC 3/8 — 24 UNF 7/16 — 14 UNC 7/16 — 20 UNF 1/2 — 13 UNC 1/2 — 20 UNF 5/8 — 11 UNC 5/8 — 18 UNF 3/4 — 10 UNC 3/4 — 16 UNF 7/8 — 9 UNC 7/8 — 14 UNF 16 + 2 17 + 2 27 + 3 29 + 3 30 + 3 32 + 4 65 + 10 75 + 10 93 + 12 115 + 15 140 + 20 155 + 25 18 + 2 13 + 2 10 + 2 in-lb 13 + 2 N-cm 147 + 23 in-lb 15 + 2 17 + 2 N-cm 169 + 23 192 + 23 328 + 34 350 + 45 475 + 56 542 + 56 1130 + 113 1299 + 136 2260 + 282 2542 + 282 N-m 41 + 4 47 + 5 68 + 7 75 + 8 102 + 11 115 + 12 203 + 20 230 + 24 359 + 37 407 + 41 583 + 61 ….. …

Wikipedia’s page for Toro Company

Company Web Site: www.toro.com

Toro 08164SL Service Manual Workman MDE Preface Publication Service - 1 of 112

Toro 08164SL Service Manual Workman MDE Preface Publication Service - 1 of 112 Toro 08164SL Service Manual Workman MDE Preface Publication Service - 2 of 112

Toro 08164SL Service Manual Workman MDE Preface Publication Service - 2 of 112 Toro 08164SL Service Manual Workman MDE Preface Publication Service - 3 of 112

Toro 08164SL Service Manual Workman MDE Preface Publication Service - 3 of 112 Toro 08164SL Service Manual Workman MDE Preface Publication Service - 4 of 112

Toro 08164SL Service Manual Workman MDE Preface Publication Service - 4 of 112 Toro 08164SL Service Manual Workman MDE Preface Publication Service - 5 of 112

Toro 08164SL Service Manual Workman MDE Preface Publication Service - 5 of 112 Toro 08164SL Service Manual Workman MDE Preface Publication Service - 6 of 112

Toro 08164SL Service Manual Workman MDE Preface Publication Service - 6 of 112 Toro 08164SL Service Manual Workman MDE Preface Publication Service - 7 of 112

Toro 08164SL Service Manual Workman MDE Preface Publication Service - 7 of 112 Toro 08164SL Service Manual Workman MDE Preface Publication Service - 8 of 112

Toro 08164SL Service Manual Workman MDE Preface Publication Service - 8 of 112 Toro 08164SL Service Manual Workman MDE Preface Publication Service - 9 of 112

Toro 08164SL Service Manual Workman MDE Preface Publication Service - 9 of 112 Toro 08164SL Service Manual Workman MDE Preface Publication Service - 10 of 112

Toro 08164SL Service Manual Workman MDE Preface Publication Service - 10 of 112