From inside (document excerpt):

PART NO. 98958SL (Rev. C) Service Manual ReelmasterR 4000-D Preface The purpose of this publication is to provide the service technician with information for troubleshooting, testing, and repair of major systems and components on the Reelmaster 4000-D. REFER TO THE TRACTION UNIT AND CUTTING UNIT OPERATOR’S MANUALS FOR OPERATING, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS. Space is provided in Chapter 2 of this book to insert the Operator’s Manuals and Parts Catalogs for your machine.

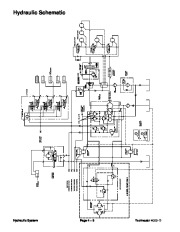

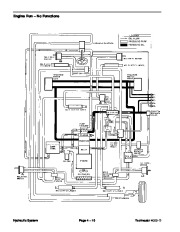

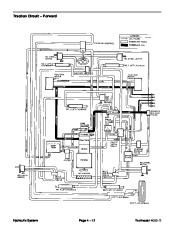

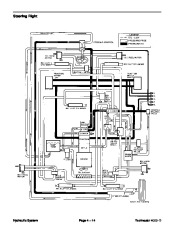

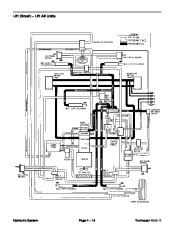

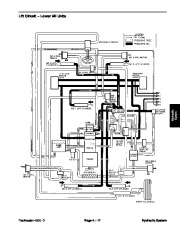

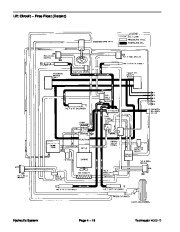

Replacement Operator’s Manuals are available by sending complete Model and Serial Number to: The Toro Company 8111 Lyndale Avenue South Bloomington, MN 55420-1196 The Toro Company reserves the right to change product specifications or this publication without notice. This safety symbol means DANGER, WARNING, or CAUTION, PERSONAL SAFETY INSTRUCTION. When you see this symbol, carefully read the instructions that follow. Failure to obey the instructions may result in personal injury. NOTE: A NOTE will give general information about the correct operation, maintenance, service, testing, or repair of the machine. IMPORTANT: The IMPORTANT notice will give important instructions which must be followed to prevent damage to systems or components on the machine. E The Toro Company – 1998, 2003, 2005, 2007 Reelmaster 4000-D Table Of Contents Chapter 1 – Safety General Safety Instructions 1 – 1 Safety and Instruction Decals 1 – 4 Chapter 2 – Product Records and Maintenance Product Records . Equivalents and Conversions Torque Specifications . Lubrication Chapter 3 – Kubota Diesel Engine Introduction Specifications General Information Adjustments . Service and Repairs KUBOTA WORKSHOP MANUAL, 03 SERIES, DIESEL ENGINE 3-2 3-3 3-4 3-7 3-8 2-1 2-2 2-3 2-7 Chapter 4 – Hydraulic System Specifications 4 – 2 General . 4 – 3 Hydraulic Schematic 4 – 8 Hydraulic Flow Diagrams 4 – 9 4WD Selector Valve Operation 4 – 24 Special Tools . 4 – 26 Troubleshooting . 4 – 28 Testing . 4 – 30 Service and Repairs . 4 – 39 Chapter 5 – Electrical System Electrical Schematics and Diagrams 5 – 2 Special Tools . 5 – 15 Troubleshooting . 5 – 16 Electrical System Quick Check 5 – 19 Component Testing 5 – 20 Service and Repairs . 5 – 31 Chapter 6 – Axles and Brakes Specifications 6 – 2 Adjustments . 6 – 3 Service and Repairs 6 – 5 Chapter 7 – Cutting Units Specifications Special Tools Adjustments . Service and Repairs 7-2 7-3 7-4 7-8 Reelmaster 4000-D Rev. C Cutting Units Axles and Brakes Electrical System Hydraulic System Kubota Diesel Engine Product Records and Maintenance Safety Reelmaster 4000-D Chapter 1 Safety GENERAL SAFETY INSTRUCTIONS Before Operating While Operating Maintenance and Service 1 1 2 3 SAFETY AND INSTRUCTION DECALS 4 Safety Table of Contents General Safety Instructions The Reelmaster 4000-D was tested and certified by TORO for compliance with the B71.4-1984 specifications of the American National Standards Institute for riding mowers when rear tires are filled with calcium chloride and two rear wheel weight kits. Although hazard control and accident prevention partially are dependent upon the design and configuration of the machine, these factors are also dependent upon the awareness, concern, and proper training of the personnel involved in the operation, transport, maintenance, and storage of the machine. Improper use or maintenance of the machine can result in injury or death. WARNING To reduce the potential for injury or death, comply with the following safety instructions. Before Operating 1. Read and understand the contents of the traction unit and cutting unit operator’s manuals before operating the machine. To get replacement manuals, send complete model and serial number to: The Toro Company 8111 Lyndale Avenue South Minneapolis, MN 55420-1196 2. Never allow children to operate the machine or adults to operate it without proper instruction. 3. Become familiar with the controls and know how to stop the machine and engine quickly. 4. Keep all shields, safety devices and decals in place. If a shield, safety device or decal is defective or damaged, repair or replace it before operating the machine. 5. Always wear substantial shoes. Do not operate machine while wearing sandals, tennis shoes, sneakers or when barefoot. Do not wear loose fitting clothing that could get caught in moving parts and possibly cause personal injury. 6. Wearing safety glasses, safety shoes, long pants and a helmet is advisable and required by some local ordinances and insurance regulations. 7. Make sure the work area is clear of objects which might be picked up and thrown by the reels. 8. Do not carry passengers on the machine. Keep everyone, especially children and pets, away from the areas of operation. 9. Since diesel fuel is highly flammable, handle it carefully: A. Use an approved fuel container. B. Do not remove fuel tank cap while engine is hot or running. C. Do not smoke while handling fuel. D. Fill fuel tank outdoors and only to within an inch (25 mm) from the top of the tank, not the filler neck. Do not overfill. E. Wipe up any spilled fuel. Reelmaster 4000-D Page 1 – 1 Safety While Operating 10. Do not run engine in a confined area without adequate ventilation. Exhaust is hazardous and could be deadly. 11. Sit on the seat when starting and operating the machine. 12. Check interlock switches daily for proper operation. If a switch fails, replace it before operating the machine. The interlock system is for your protection, so do not bypass it. Replace all interlock switches every two years. 13. This product may exceed noise levels of 85 dB(A) at the operator position. Ear protectors are recommended for prolonged exposure to reduce the potential of permanent hearing damage. 14. Before starting the engine each day, test lamps, warning buzzer and signal lights to assure proper operation. 15. Pay attention when using the machine. To prevent loss of control: A. Mow only in daylight or when there is good artificial light. B. Watch for holes or other hidden hazards. C. Be extremely careful when operating close to sand traps, ditches, creeks, steep hillsides or other hazards. D. Reduce speed when making sharp turns. Avoid sudden stops and starts. Use ground speed limiter lever to set pedal travel so excessive ground speed will be avoided during mowing and transport. E. Look to the rear to assure no one is behind the machine before backing up. F. Watch for traffic when near or crossing roads. Always yield the right-of-way. G. Reduce speed when driving downhill. 16. Keep hands, feet, andclothing away from moving parts and the reels. E. Do not park on slopes unless wheels are chocked or blocked. 25. The optional TORO tow bar is for emergency towing only. Use only the special tow bar if it becomes necessary to tow machine. Use trailer for normal transport. 17. Traverse slopes carefully. Do not start or stop suddenly when traveling uphill or downhill. 18. Operator must be skilled and trained in how to drive on hillsides. Failure to use caution on slopes or hills may cause loss of control and vehicle to tip or roll possibly resulting in personal injury or death. 19. When operating 4 wheel drive machine, always use the seat belt and ROPS together and have seat pivot retaining pin installed. 20. If engine stalls or loses headway and cannot make it to the top of a slope, do not turn machine around. Always back slowly straight down the slope. 21. Raise cutting units and latch them securely in transport position before driving from one work area to another. 22. Do not touch engine, muffler or exhaust pipe while engine is running or soon after it is stopped. These areas could be hot enough to cause burns. 23. If cutting unit strikes a solid object or vibrates abnormally, stop immediately, turn engine off, set parking brake and wait for all motion to stop. Inspect for damage. If reel or bedknife is damaged, repair or replace it before operating. Do not attempt to free blocked cutting unit by moving Mow/Backlap lever rapidly between FORWARD and BACKLAP. Damage to hydraulic system may result. Lever should easily return and hold in the STOP position. 24. Before getting off the seat: A. Move traction pedal to neutral. B. Set parking brake. C. Disengage cutting units and wait for reels to stop.

Wikipedia’s page for Toro Company

Company Web Site: www.toro.com

Toro 98958SL Rev C Service Manual Reelmaster 4000 D Preface Publication - Enlarge page 1 of 188

Toro 98958SL Rev C Service Manual Reelmaster 4000 D Preface Publication - Enlarge page 1 of 188 2 of 188

2 of 188 3 of 188

3 of 188 4 of 188

4 of 188 5 of 188

5 of 188 6 of 188

6 of 188 7 of 188

7 of 188 8 of 188

8 of 188 9 of 188

9 of 188 10 of 188

10 of 188 11 of 188

11 of 188 12 of 188

12 of 188 13 of 188

13 of 188 14 of 188

14 of 188 15 of 188

15 of 188 16 of 188

16 of 188 17 of 188

17 of 188 18 of 188

18 of 188 19 of 188

19 of 188 20 of 188

20 of 188 21 of 188

21 of 188 22 of 188

22 of 188 23 of 188

23 of 188 24 of 188

24 of 188 25 of 188

25 of 188 26 of 188

26 of 188 27 of 188

27 of 188 28 of 188

28 of 188 29 of 188

29 of 188 30 of 188

30 of 188 31 of 188

31 of 188 32 of 188

32 of 188 33 of 188

33 of 188 34 of 188

34 of 188 35 of 188

35 of 188 36 of 188

36 of 188 37 of 188

37 of 188 38 of 188

38 of 188 39 of 188

39 of 188 40 of 188

40 of 188 41 of 188

41 of 188 42 of 188

42 of 188 43 of 188

43 of 188 44 of 188

44 of 188 45 of 188

45 of 188 46 of 188

46 of 188 47 of 188

47 of 188 48 of 188

48 of 188 49 of 188

49 of 188 50 of 188

50 of 188