From inside (document excerpt):

Part No. 10178SL Service Manual GroundsmasterR 4300-D Preface The purpose of this publication is to provide the service technician with information for troubleshooting, testing and repair of major systems and components on the Groundsmaster 4300–D. REFER TO THE OPERATOR’S MANUAL FOR OPERATING, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS. Space is provided in Chapter 2 of this book to insert the Operator’s Manual and Parts Catalog for your machine.

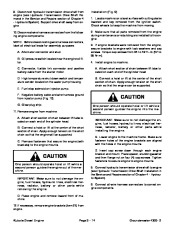

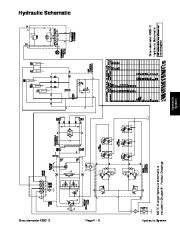

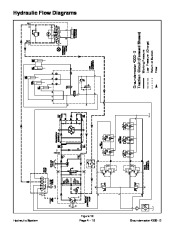

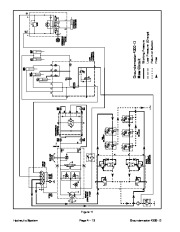

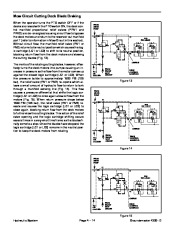

Additional copies of the Operator’s Manual and Parts Catalog are available on the internet at www.Toro.com. The Toro Company reserves the right to change product specifications or this publication without notice. This safety symbol means DANGER, WARNING, or CAUTION, PERSONAL SAFETY INSTRUCTION. When you see this symbol, carefully read the instructions that follow. Failure to obey the instructions may result in personal injury. NOTE: A NOTE will give general information about the correct operation, maintenance, service, testing or repair of the machine. IMPORTANT: The IMPORTANT notice will give important instructions which must be followed to prevent damage to systems or components on the machine. E The Toro Company – 2010 This page is intentionally blank. Groundsmaster 4300–D Table Of Contents Safety Foldout Drawings Groundsmaster 4300–D Cutting Decks Chassis Electrical System Hydraulic System Kubota Diesel Engine Product Records and Maintenance Chapter 1 – Safety Safety Instructions 1 — 2 Jacking Instructions . 1 — 5 Safety and Instruction Decals 1 — 6 Chapter 2 – Product Records and Maintenance Product Records . Maintenance . Equivalents and Conversions Torque Specifications . Chapter 3 – Kubota Diesel Engine General Information 3 — 1 Specifications 3 — 2 Adjustments . 3 — 3 Service and Repairs 3 — 4 KUBOTA WORKSHOP MANUAL, DIESEL ENGINE, 05–E3B SERIES Chapter 4 – Hydraulic System Specifications 4 — 2 General Information 4 — 3 Hydraulic Schematic 4 — 9 Hydraulic Flow Diagrams . 4 — 10 Special Tools . 4 — 22 Troubleshooting . 4 — 26 Testing . 4 — 32 Service and Repairs . 4 — 60 SAUER–DANFOSS LPV CLOSED CIRCUIT AXIAL PISTON PUMPS REPAIR MANUAL SAUER–DANFOSS LPV CLOSED CIRCUIT AXIAL PISTON PUMPS SERVICE INSTRUCTIONS PARKER TORQMOTORTM SERVICE PROCEDURE (TC, TB, TE, TJ, TF, TG, TH AND TL SERIES) SAUER–DANFOSS STEERING UNIT TYPE OSPM SERVICE MANUAL 2 -2 -2 -2 -1 1 2 3 Chapter 5 – Electrical System General Information 5 — 3 Special Tools 5 — 4 Troubleshooting 5 — 6 Electrical System Quick Checks . 5 — 17 Adjustments 5 — 19 Component Testing 5 — 22 Service and Repairs . 5 — 44 Chapter 6 – Chassis Specifications General Information Special Tools Service and Repairs Chapter 7 – Cutting Decks Specifications General Information Troubleshooting Special Tools Adjustments . Service and Repairs Chapter 8 – Foldout Drawings Hydraulic Schematic 8 — 3 Electrical Schematic 8 — 4 Wire Harness Drawings . 8 — this page is intentionally blank. Groundsmaster 4300–D Chapter 1 Safety Safety Table of Contents SAFETY INSTRUCTIONS Before Operating While Operating . Maintenance and Service JACKING INSTRUCTIONS . SAFETY AND INSTRUCTION DECALS 2 2 3 4 5 6 Groundmaster 4300–D Page 1 – 1 – Safety Safety Instructions Your Groundsmaster meets or exceeds safety standard specifications when weights are installed according to information in the Operator’s Manual. Although hazard control and accident prevention are partially dependent upon the design and configuration of the machine, these factors are also dependent upon the awareness, concern and proper training of the personnel involved in the operation, transport, maintenance and storage of the machine. Improper use or maintenance of the machine can result in injury or death. To reduce the potential for injury or death, comply with the following safety instructions. WARNING To reduce the potential for injury or death, comply with the following safety instructions. Before Operating 1. Review and understand the contents of the Operator’s Manual and Operator Training DVD before starting and operating the machine. Become familiar with the controls and know how to stop the machine and engine quickly. A replacement Operator’s Manual is available on the Internet at www.Toro.com. 2. Keep all shields, safety devices and decals in place. If a shield, safety device or decal is defective, illegible or damaged, repair or replace it before operating the machine. 3. Tighten any loose nuts, bolts or screws to ensure machine is in safe operating condition. 4. Assure interlock switches are adjusted correctly so engine cannot be started unless traction pedal is in NEUTRAL and PTO switch is OFF (disengaged). 5. Since diesel fuel is highly flammable, handle it carefully: A. Store fuel in containers specifically designed for this purpose. B. Do not remove machine fuel tank cap while engine is hot or running. C. Do not smoke while handling fuel. D. Fill fuel tank outdoors and only to within an inch of the top of the tank, not the filler neck. Do not overfill.

Wikipedia’s page for Toro Company

Company Web Site: www.toro.com

Toro 10178SL Service Manual Groundsmaster 4300 D Preface Publication - Enlarge page 1 of 255

Toro 10178SL Service Manual Groundsmaster 4300 D Preface Publication - Enlarge page 1 of 255 2 of 255

2 of 255 3 of 255

3 of 255 4 of 255

4 of 255 5 of 255

5 of 255 6 of 255

6 of 255 7 of 255

7 of 255 8 of 255

8 of 255 9 of 255

9 of 255 10 of 255

10 of 255 11 of 255

11 of 255 12 of 255

12 of 255 13 of 255

13 of 255 14 of 255

14 of 255 15 of 255

15 of 255 16 of 255

16 of 255 17 of 255

17 of 255 18 of 255

18 of 255 19 of 255

19 of 255 20 of 255

20 of 255 21 of 255

21 of 255 22 of 255

22 of 255 23 of 255

23 of 255 24 of 255

24 of 255 25 of 255

25 of 255 26 of 255

26 of 255 27 of 255

27 of 255 28 of 255

28 of 255 29 of 255

29 of 255 30 of 255

30 of 255 31 of 255

31 of 255 32 of 255

32 of 255 33 of 255

33 of 255 34 of 255

34 of 255 35 of 255

35 of 255 36 of 255

36 of 255 37 of 255

37 of 255 38 of 255

38 of 255 39 of 255

39 of 255 40 of 255

40 of 255 41 of 255

41 of 255 42 of 255

42 of 255 43 of 255

43 of 255 44 of 255

44 of 255 45 of 255

45 of 255 46 of 255

46 of 255 47 of 255

47 of 255 48 of 255

48 of 255 49 of 255

49 of 255 50 of 255

50 of 255