From inside (document excerpt):

Commercial Products Hydraulics Hydrostatics Schematics and Test Equipment Part No. 82356SL, Rev. B Introduction Turf mowing equipment was very cumbersome and inefficient when it was first developed back in the early 1900’s. Improvements were made through the years of Turf equipment’s development, but it wasn’t until hydraulics became a part of the design that significant improvements were made. Use of hydraulics has increased to form a major portion of turf product designs.

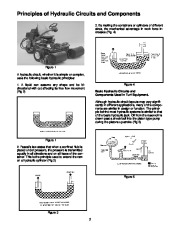

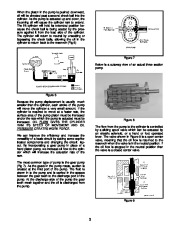

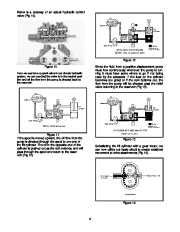

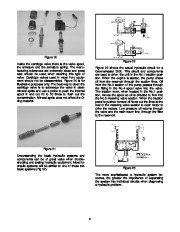

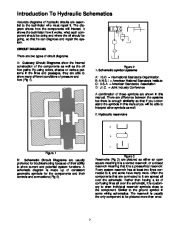

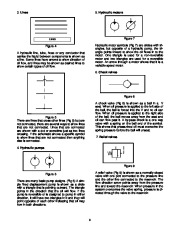

Increases efficiency, reliability, lowered maintenance costs, safer products and improved operator comfort are all byproducts of the increase in use of hydraulic systems on turf products. An understanding of hydraulic systems and their function on a product, is a necessity to properly service, adjust, troubleshoot or test turf products. INDEX 1: HYDRAULIC PRINCIPLES, PAGE 2. OBJECTIVE: To familiarize the technician with the basic fundamentals of hydraulic systems and their operation. 2: HYDRAULIC SCHEMATICS, PAGE 7. OBJECTIVE: Improve hydraulic technicians ability to read and comprehend hydraulic schematics, and apply them to various repair jobs. 3: HYDROSTATIC TRANSMISSIONS, PAGE 14. OBJECTIVE: Provide technicians with helpful information on the operation and maintenance of hydrostatic transmissions. 4: HYDRAULIC HOSES AND FITTINGS, PAGE 19. OBJECTIVE: Review proper hose and fitting service procedures. 5: TEST EQUIPMENT, PAGE 23. OBJECTIVE: Instruct technicians on the proper test equipment and procedures to effectively and safely diagnose hydraulic systems. 6: REVIEW QUESTIONS, PAGE 27. Review Answers Principles of Hydraulic Circuits and Components 3. By making the containers or cylinders of different sizes, the mechanical advantage in work force increases (Fig. 4) Figure 1 A hydraulic circuit, whether it is simple or complex, uses the following basic hydraulic principles: 1. A liquid can assume any shape and be bidirectional with out affecting its free flow movement (Fig 2) Figure 4 Basic Hydraulic Circuits and Components Used in Turf Equipment. Although hydraulic circuit layouts may vary significantly in different applications, many of the components are similar in design or function. The principle behind most hydraulic systems is similar to that of the basic hydraulic jack. Oil from the reservoir is drawn past a check ball into the piston type pump during the pistons up-stroke (Fig 5) Figure 1 2. Pascal’s law states that when a confined fluid is placed under pressure, the pressure is transmitted equally in all directions and on all faces of the container. This is the principle used to extend the ram on a hydraulic cylinder (Fig 3) Figure 5 Figure 3 2 When the piston in the pump is pushed downward, oil will be directed past a second check ball into the cylinder. As the pump is actuated up and down, the incoming oil will cause the cylinder ram to extend. The lift cylinder will hold its extended position because the check ball is being seated by the pressure against it from the load side of the cylinder. The cylinder will return to neutral by unseating or bypassing the check balls, allowing the oil in the cylinder to return back to the reservoir (Fig.6) Figure 7 Below is a cutaway view of an actual three section pump. Figure 6 Because the pump displacement is usually much smaller than the cylinder, each stroke of the pump will move the cylinder a very small amount. If the cylinder is required to move at a faster rate, the surface area of the pump piston must be increased and/or the rate which the pump is actuated must be increased. OIL FLOW GIVES THE CYLINDER RAM ITS SPEED OF MOVEMENT AND OIL PRESSURE CREATES WORK FORCE. We can improve the efficiency and Increase the versatility of a basic circuit by adding some sophisticated components and changing the circuit layout. By incorporating a gear pump in place of a hand piston pump, we increase oil flow to the cylinder which will increase the actuation rate of the ram. The most common type of pump is the gear pump (Fig 7). As the gears in the pump rotate, suction is created at the inlet port of the pump. The fluid is drawn in to the pump and is carried in the spaces between the gear teeth to the discharge port of the pump. At the discharge side of the pump the gear teeth mesh together and the oil is discharged from the pump. Figure 8 The flow from the pump to the cylinder is controlled by a sliding spool valve which can be actuated by an electric solenoid, or a hand or foot operated lever. The valve shown in Figure 9 is a open center valve, meaning that the oil flow is returned to the reservoir when the valve is in the neutral position. If the oil flow is stopped in the neutral position than the valve is a closed center valve. Figure 9 3 Below is a cutaway of an actual hydraulic control valve (Fig 10). Figure 12 Figure 10 Here we see have a spool valve in our simple hydraulic system, we can see that the valve is in the neutral position and all the flow from the pump is directed back to the reservoir. Since the fluid from a positive displacement pump must flow continuously whenever the pump is running it must have some where to go if not being used by the actuators. If the load on the cylinder becomes too great or if the ram bottoms out, the flow from the pump will be directed past the relief valve returning to the reservoir (Fig 13). Figure 11 If the spool is moved upward, the oil flow from the pump is directed through the spool to one end of the lift cylinder. The oil in the opposite end of the cylinder is pushed out as the ram extends, and will pass through the spool and return to the reservoir.(Fig 12). Figure 13 Substituting the lift cylinder with a gear motor, we can now utilize out basic circuit to create rotational movement to drive attachments (Fig 14). Figure 14 4 Figure 15 shows a hydraulic reel motor. solenoid valves and the internal porting to make the valve operate (Fig 18). The outer ports on the valve body are threaded to allow hoses and lines to be connected to the valve body. Care should be taken when tightening the hose and line fittings so the valve is not distorted by over tightening of the connections. Tighten the line and hose connections to the correct Flats From Finger Tight (F.F.F.T.) spec. listed in the service manual. Figure 15 Figure 16 illustrates the basic circuit and components necessary to drive the reel cutting units. With the spool in the upward position, the oil flow is directed through the spool valve to the lower port driving the motor in the forward direction. Figure 18 The electric solenoid valve operates by supplying electrical current to a coil magnet, the magnetic field moves a valve spool and this directs the oil. The thing to remember is that the only difference between a hydraulic electric valve, and a regular hydraulic valve is the way that the spool is moved. Figure 16 Actuating the spool to the down position, the flow of oil from the pump is directed to the opposite port of the motor. The motor than rotates in the reverse direction (Fig 17). Figure 19 The solenoid valves consist of the valve cartridge and the solenoid coil (Fig 19). To disassemble the valve remove the coil assembly and then carefully unscrew the valve body. The O-rings and seals should be replaced whenever a valve body is removed or replaced. Figure 17 Another type of valve system becoming popular in turf equipment is the electric solenoid type valve system. The solenoid valve system consists of a machined valve body. This valve body contains the 5 Figure 20 Inside the cartridge valve there is the valve spool, the armature and the armature spring. The manufacturing tolerances are extremely close and great care should be used when cleaning this type of valve. Cartridge valves used in most Toro equipment should not be disassembled. Figure 20 is for illustrative purposes only. The best way to clean the cartridge valve is to submerge the valve in clean mineral sprits and use a probe to push the internal spool in and out 20 to 30 times to flush out the contamination. Mineral sprits does not affect the Oring material. Figure 22 Figure 23 shows the actual hydraulic circuit for a Greensmaster 3000. This circuit and components are used to drive the unit in the No.1 traction position. When the engine is started, the pump draws oil from the reservoir through the suction lines. Oil from the No.4 section of the pump passes through the fitting in the No.4 spool valve into the valve. The traction lever, when located in the No.1 position, moves the spool so oil is directed to flow into the No.5 metering valve section. When the traction pedal is pushed forward oil flows out the lines at the rear of the metering valve section to each motor to drive the motors. Low pressure oil returns through the valve and the main return line, through the filter to the reservoir. Figure 21 Understanding the basic hydraulic systems and components can be of great value when troubleshooting and testing hydraulic equipment. Most hydraulic systems will be similar to one of these two basic systems (Fig 22). Figure 23 The more sophisticated a hydraulic system becomes, the greater the importance of separating the system into individual circuits when diagnosing a hydraulic problem.

Wikipedia’s page for Toro Company

Company Web Site: www.toro.com

Toro Commercial Products Hydraulics Hydrostatics Schematics Test Equipment 82356SL Rev B - 1 of 32

Toro Commercial Products Hydraulics Hydrostatics Schematics Test Equipment 82356SL Rev B - 1 of 32 Toro Commercial Products Hydraulics Hydrostatics Schematics Test Equipment 82356SL Rev B - 2 of 32

Toro Commercial Products Hydraulics Hydrostatics Schematics Test Equipment 82356SL Rev B - 2 of 32 Toro Commercial Products Hydraulics Hydrostatics Schematics Test Equipment 82356SL Rev B - 3 of 32

Toro Commercial Products Hydraulics Hydrostatics Schematics Test Equipment 82356SL Rev B - 3 of 32 Toro Commercial Products Hydraulics Hydrostatics Schematics Test Equipment 82356SL Rev B - 4 of 32

Toro Commercial Products Hydraulics Hydrostatics Schematics Test Equipment 82356SL Rev B - 4 of 32 Toro Commercial Products Hydraulics Hydrostatics Schematics Test Equipment 82356SL Rev B - 5 of 32

Toro Commercial Products Hydraulics Hydrostatics Schematics Test Equipment 82356SL Rev B - 5 of 32 Toro Commercial Products Hydraulics Hydrostatics Schematics Test Equipment 82356SL Rev B - 6 of 32

Toro Commercial Products Hydraulics Hydrostatics Schematics Test Equipment 82356SL Rev B - 6 of 32 Toro Commercial Products Hydraulics Hydrostatics Schematics Test Equipment 82356SL Rev B - 7 of 32

Toro Commercial Products Hydraulics Hydrostatics Schematics Test Equipment 82356SL Rev B - 7 of 32 Toro Commercial Products Hydraulics Hydrostatics Schematics Test Equipment 82356SL Rev B - 8 of 32

Toro Commercial Products Hydraulics Hydrostatics Schematics Test Equipment 82356SL Rev B - 8 of 32 Toro Commercial Products Hydraulics Hydrostatics Schematics Test Equipment 82356SL Rev B - 9 of 32

Toro Commercial Products Hydraulics Hydrostatics Schematics Test Equipment 82356SL Rev B - 9 of 32 Toro Commercial Products Hydraulics Hydrostatics Schematics Test Equipment 82356SL Rev B - 10 of 32

Toro Commercial Products Hydraulics Hydrostatics Schematics Test Equipment 82356SL Rev B - 10 of 32